Last fall I got an inexpensive 3D printer (Ender 3 Pro) and have been surprised at how it’s made “shop life” better. What are your favorite things you’ve made for your shop? Here are mine:

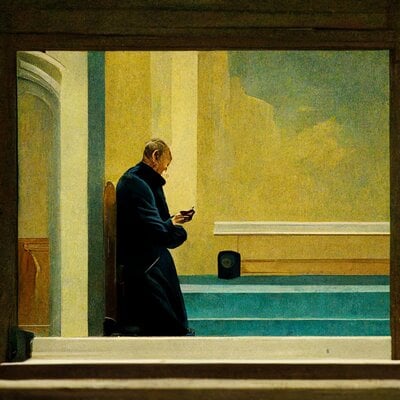

Pictued above, this have 100% solved how to store these things. Just printed with PLA, they’re quite strong and fit the tools perfectly.

#2: Tool Well Storage Bins

I made these to fit my bench’s tool well. I had been using jars and other round containers but their shape wasted space and they didn’t have internal divisions.

Nice way to keep my most often used bits out of a drawer and easy to find.

#4: 4" x 120mm Dust Hose Adapter

While not glamorous I use this every time I use my table saw.

i keep going back and forth trying to justify a 3dp - think you’ve just convinced me :) any pointers on a good setup to do what you’re doing here?

Most decent printers will work for that sort of thing, I definitely recommend a heated print bed. Top advice: learn CAD. Master it. Then you can make almost anything.

Also be prepared for a lot of frustration. I’ve been printing for a little under two years now and there are points where I just had to walk away from it for a month or two because my level of frustration had reached its peak.

Keep your filament dry and in big ziploc bags with desiccant packs when not in use.

I actually made a bin into a filament storage box. Used an 1.25" dowel to support 4 rolls over silica cat litter. There’s an exit port for each roll, so I can run my 4 most used filaments right from the box.

Like Null said, git gud at CAD. I like Fusion360 (is/was free for personal use) for that and it’s always been able to let me build the nonsense I needed.

I’ve had a few printers over the last 6 years and while people say creality’s quality has dropped a lot recently, prior to that I was using a CR10S like a workhorse and it was amazing. Just recently picked up a Sovol SV05 and it’s been great too. First time with auto leveling and while i don’t fully understand how to use it properly, it is way easier than manually managing the bed level. So, if you get one, make sure it has some form of auto leveling. It’ll save you many failed prints.

I’m doing basic, functional stuff so there’s thankfully not much to figure out. I haven’t done any mods to my printer. The bed stays level as long as I’m gentle while removing the print.

The only thing I’ve struggled with was layer and bed adhesion during cold weather. To solve that I made a simple enclosure and also slowed down my first layer.

Do you have a library nearby? Lots of them have printers you can use.

I would recommend a printer with automatic bed leveling (ABL), at some point you want it and installing it later, while possible on many printers, is a hassle. I was sitting on the fence a long time myself. Ended up buying a “FLSUN Q5” as my first printer and I couldn’t be happier.

I know there’s some pushback at delta printers for first timers, but I just love how it looks when they print.

Oh yeah… And be sure to never let your filament get tangled!!! Google that before you get started 😂

I would recommend a printer with automatic bed leveling (ABL), at some point you want it and installing it later, while possible on many printers, is a hassle. I was sitting on the fence a long time myself. Ended up buying a “FLSUN Q5” as my first printer and I couldn’t be happier.

I know there’s some pushback at delta printers for firsttimers, but I just love how it looks when they print.

I made a screw identifier for work. Length and size. Great for machine operators

As a first-time framer, I used freecad to throw together some exact birdsmouths templates out of PETG (they look like a speed square). I don’t know if they were necessary, but having them takes a lot of stress off and the print was about an hour for 2 - one for the ridge beam, one for the wall with sheathing

Dust hose adapter - why didn’t I think of that!?!

That’ll be going on my “to print” list :)

Dust collection is a great application for 3D printing… Years ago I broke the bag adapter for my sanding station so I made a replacement!

We’ve recently bought our first home and move in next month. I’m really looking forward to setting up my workshop with things like this :)

Exciting stuff! Good luck with the move.

Thanks :)

I bought a 3d printer (Sidewinder X1) based on it’s capacity to print up a 100mm cyclone for chip separation. Making that, and some dust collection fittings for my Kity 636 planer thicknesser (both .stl files available through thingiverse) have easily repaid the c.£150 I paid for the printer.

There are also loads of options for magnetic dust collection fittings, which make an amazing difference when you have one extractor and many machines.

Don’t forget router templates! I’ve made so many of those now in various shapes and sizes that it almost feels like delayed reaction cnc routing. :)

A set of corner templates has been extremely useful for me. I found a minimum of five passes for the walls to maintain their shape over time.

Something like: https://www.thingiverse.com/thing:2438336/files

i will be printing a few of these, thanks for the links!